What is Altair Inspire Cast?

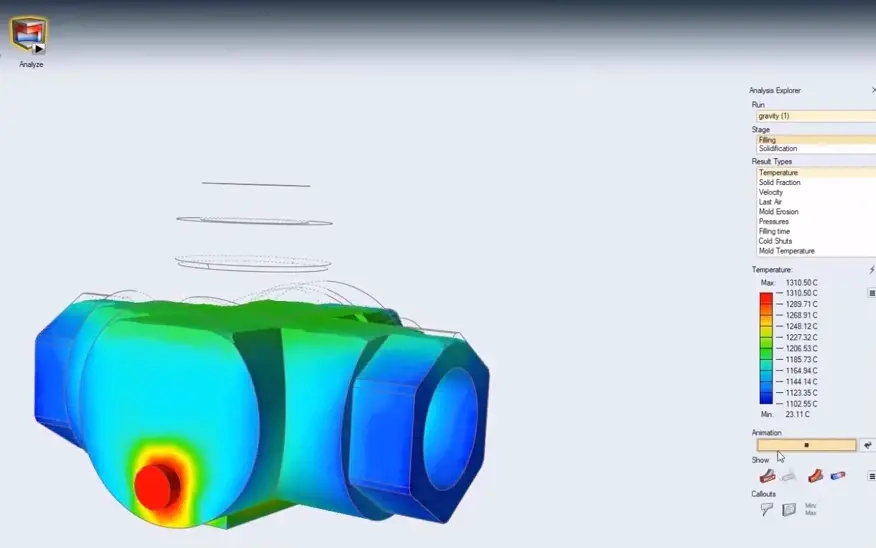

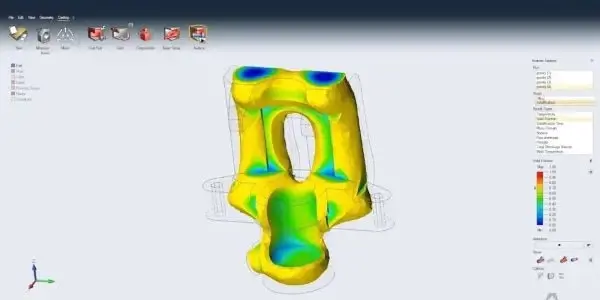

Altair Inspire Cast (formerly Click2Cast) software is a fast, easy, accurate, and affordable casting simulation environment focused on creating high-quality components with increased profitability through a highly intuitive user experience. It is the only tool that caters to beginners and experts alike, from product designers to foundry engineers.

Right from the early design phase, users can visualize typical casting defects such as air entrapment, shrinkage porosity, cold shuts, mold degradation and rectify them avoiding costly downstream corrections. Guided process templates offer five easy steps to simulate gravity die, gravity sand, investment, high pressure, low-pressure die casting, and tilt pouring.

Key Capabilities

- Avoid costly casting defects like air entrapment, shrinkage porosity, cold shuts and mold degradation

- Simple 5 step process makes running analysis simple and easy to understand

- Multiple casting process templates included: Gravity die, gravity sand, investment, high pressure and low pressure casting.

- Parallel processing capabilities reduces simulation times, usually to within minutes

Altair Inspire Cast Customer Stories

Hadleigh Castings

Minimizing costs and maximizing yield with a simulation approach to casting method development