Altair Inspire Cast Components: Chiller

Altair Inspire Cast features many component types that you can include in your casting simulation. One component that can be used to control the solidification of your model is the chiller.

What is a Chiller?

A chiller, chill, or chill block is a piece of material (usually a metal block at room temperature) that sits in the mold before casting is poured. The name “chiller” comes from the function of this material which is to help cool or “chill” the molten metal that contacts it. This gives foundries more control over the cooling and solidification process.

Figure 1 shows a simple schematic of how a casting may cool without a chiller.

Figure 1 – No chiller; as the casting cools, molten regions may split off from one another.

The regions in red show the molten metal which, as the casting cools, may split into two separate cooling regions leading to multiple porous zones in the casting.

Figure 2 shows the same casting with chillers added.

Figure 2 – With chiller (in blue); the molten material solidification pattern is pushed by the “cooling pressure” from the chillers.

The chillers exert a kind of “cooling pressure” onto the casting to eliminate one of the porous zones and the other porous zone might be aided with a riser. With this additional control on the cooling process, we have more flexibility to achieve a good casting.

Inspire Cast Chiller

To add chillers to your Inspire Cast simulations, simply select roughly where you want to place them (Figure 3). You can hold down the Alt key to override any undesirable snapping.

Figure 3 – Add chillers to your castings.

You can then drag the position and set the material, initial temperature, and size in the dialog.

Figure 4 – Chiller settings; material, position, temperature, and size are set here.

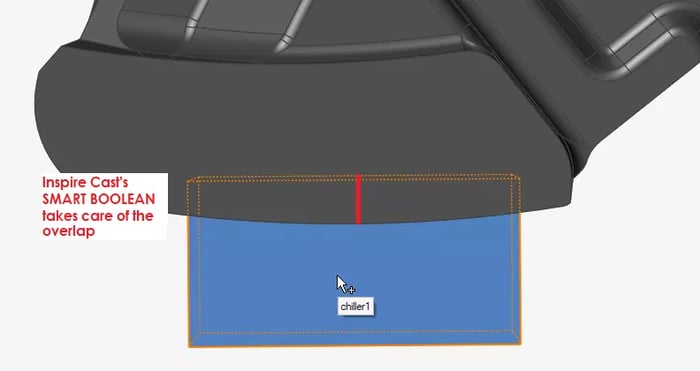

The chiller body will overlap your existing casting (Figure 5) which Inspire Cast’s smart boolean features will automatically prioritize the casting body to resolve the overlap.

Figure 5 – Overlap between chiller and casting bodies.

And now you are ready to run your casting simulation.

Inspire Cast Results

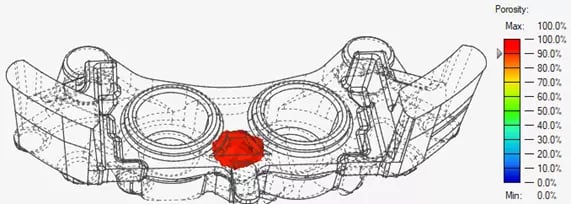

First, we ran the casting simulation without chillers for comparison. A results animation showing the solidification region is shown in Figure 6.

Figure 6 – No Chiller solidification animation (above) and porosity regions (below).

These three separate solidification zones may each need risers to help reduce porosity levels. Compare this to the results of using chillers on both edges of the part in Figure 7.

Figure 7– Chiller solidification animation (above) and porosity region (below).

With the added chillers, we now have a single solidification zone which is much easier to manage.

Summary

With Altair Inspire Cast, you can test out chiller sizes and locations on your metal castings virtually with only a few clicks of the mouse. The ability to visualize the results on-screen can help lead to overall better design decisions when confronted with creating a new casting.